Product Categories:Integrated Power System

GQH-T Intelligent Integrated AC/DC Power System

Product model: GQH-T

Product Introduction: GQH-T Intelligent Integrated AC/DC Power System is mainly composed of low voltage AC power subsystem, DC power subsystem, inverter (INV) subsystem, DC/DC communication power subsystem, AC uninterrupted power supply (UPS) subsystem. By adopting network communication, integrated monitoring, linkage and other schemes, the system effectively integrates the subsystems such as substation AC, substation DC, and UPS, uniformly collects each substation subsystem data, and implements the unified monitoring and management through integrated monitoring equipment. Integrated monitoring module communicates with the host computer system via the Ethernet interface/ IEC61850 protocol, so as to make the substation power system be an open one.

Application Scope:

1.Various voltage levels (6KV-1000KV) of substation, power plant, cement plant, chemical plant, iron&steel plant, coal mill and electrified railway.

2. Digital substation,Green substation, intelligent substation, programmed substation.

Primary Schematic Diagram of Intelligent Integrated AC/DC Power System:

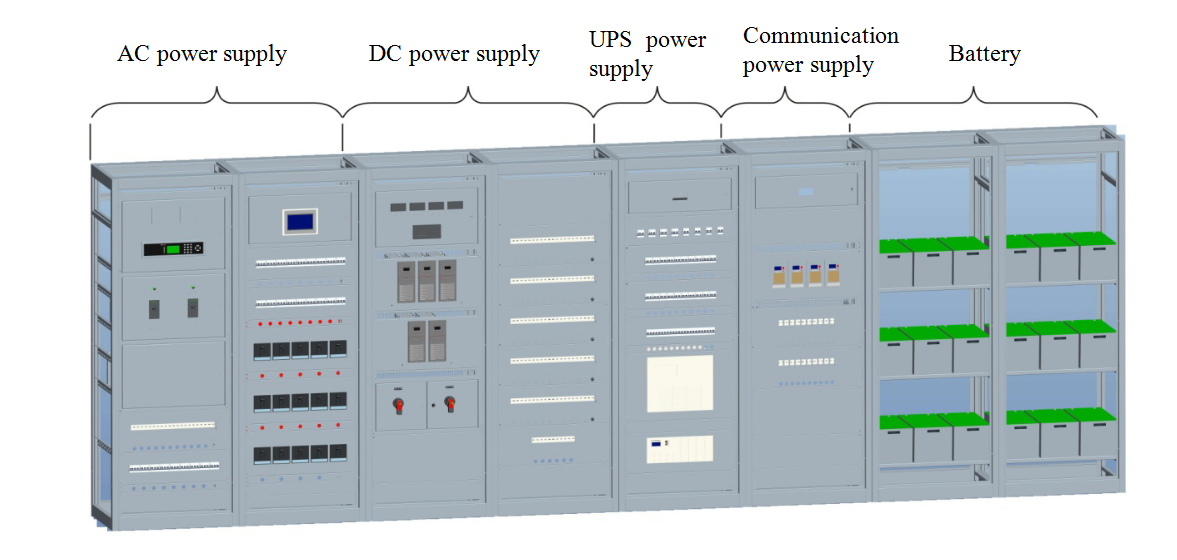

Plane Layout of Intelligent Integrated AC/DC Power System:

System Characteristics:

1. Integrated design: can realize the unified detection and management of the entire system;

2. Optimize the original monitoring module circuit, reduce the power consumption, and realize the goal of low carbon, environmental protection;

3. Integrated monitoring: use the mainstream, stable LINUX operating system kernel, and can operate more stably and reliably;

4. For the section of AC power, use dual-circuit AC input, and can select automatic or manual switching;

5. The system can provide uninterrupted AC and DC power supply;

6. The system input voltage range is wide, and its adaptability is strong;

7. Multi-module parallel design: flexible configuration of capacity, N+1 redundant backup, independent-current sharing between charging modules;

8.Monitoring system can effectively realize the monitoring of charging module, communication power module, INV/UPS power supply, AC/DC power distribution, etc., and also can provide dry contact alarm, display, audible and visual alarm;

9. Realize the local and remote monitoring on all the system parameters, and it can meet "four remotes" and unattended needs;

10. According to the battery charging and discharging curve, the battery can be managed intelligently, which can effectively prolong the service life of the battery, meanwhile multi groups of batteries can be managed at the same time.

I. Operating Environment

1. Operating temperature: -5℃-40 ℃;

2. Storage temperature: -25 ℃-70 ℃;

3. Max. relative humidity: ≤ 95% (daily average);

4. Seismic capacity: horizontal acceleration: 0.3g; vertical acceleration: 0.15g;

5. In the used site, there must not be any explosive, dangerous media; the surrounding media shall not contain any corrosive metal or gas and conductive media which can damage the insulation; it is not allowed to be full of water vapor or appear any more severe mold;

6. In the used site, there should be some facilities to prevent the rain, snow and sand;

7. The induction intensity of external magnetic field shall be not more than 0.5 m T at any direction of the used site.

II. Product Subsystem Parameters and Function descriptions

1. AC power subsystem

a. Parameters

Table 1 Parameter List of Substation AC Power Supply

No.

Items

Indexes

Remarks

1

AC input voltage

Nominal value: 380V;Allowable variation range: ±15%

3-phase 4-wire system

2

Power grid frequency

Nominal value: 50Hz;Allowable variation range:±10%

3

Input overvoltage alarm

Can be set (default value:255Vac±2Vac)

4

Input overvoltage switching point

255Vac±2Vac

Phase voltage,2-circuit AC power supply, automatic switching action point. (can be set)

5

Input under voltage alarm

Can be set (default value:185Vac±2Vac)

Phase voltage

6

Input under voltage switching point

185Vac±2Vac

Phase voltage,2-circuit AC power supply, automatic switching action point.(can be set)

b. Functions

1.Configured with AC incoming line monitoring module and can monitor three-phase voltage, three-phase current of AC incoming line, three-phase voltage, three-phase current of AC bus, active power, reactive power, frequency, power factor and other electrical parameters, so as to realize automatic switching function of standby power supply;

2. Can monitor current data of AC feeder line, closing / opening state of feeder line switch, and switch accident trip signal. For the important feeder line with some requirements, remote control function can be achieved; and for the high-end application requirements, U, I, f, P, Q, Wp, Wq and other parameters of each feeder line also can be detected.

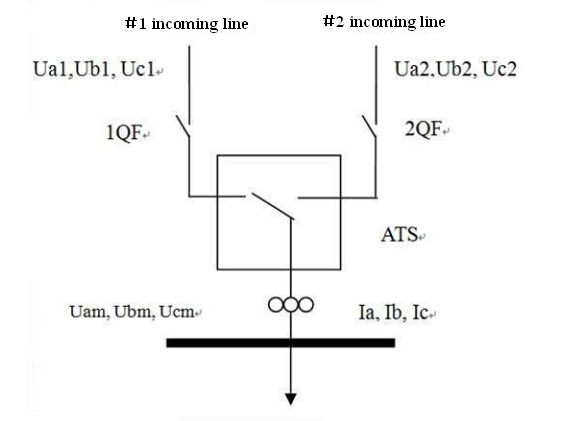

c. Schematic diagram (ATS scheme)

1Ua1, Ub1, Uc1: three-phase voltage of incoming line 1; Ua2,Ub2,Uc2: three-phase voltage of incoming line 2; Uam, Ubm, Ucm: three-phase voltage of bus; Ia, Ib, Ic: three-phase current of bus;1QF, 2QF: switch of incoming line 1 and 2 ,respectively.

Principle of operation: For dual- circuit substation transformer outputs, one of them is connected to low-voltage AC power supply bus through dual power automatic switching unit, and the other is standby; then distribute the power through the AC feeder line switch, so as to provide the power for lighting, fan, fire pump, AC load of DC power system, and etc.

2. DC power subsystem

a. Parameters

Table 2 Parameter List of DC Operating Power Supply

|

No. |

Items |

Indexes |

Remarks |

|

1 |

DC rated voltage |

220Vdc /110Vdc |

|

|

2 |

DC voltage range |

198Vdc-286Vdc /99Vdc-143Vdc |

|

|

3 |

Precision of stabilized voltage· |

≤±0.5% |

|

|

4 |

Precision of stabilized current |

≤±0.5% |

|

|

5 |

Ripple factor |

≤0.5% |

|

|

7 |

Output current-limiting |

(10%-110% )×rated value |

|

|

8 |

Unbalancedness of module current-sharing |

≤±3% |

|

|

9 |

Shunt circuit of closing bus |

Can be configured according to the needs |

|

|

10 |

Shunt circuit of controlling bus |

Can be configured according to the needs |

|

|

11 |

Efficiency |

≥94% (typ.) |

|

|

12 |

Noise |

≤55dB |

Air cooled charging module |

|

13 |

Closing bus overvoltage alarm |

Can be set(default value:264Vdc/132Vdc) |

|

|

14 |

Closing bus undervoltage alarm |

Can be set (default value:230Vdc/115Vdc) |

|

|

15 |

Controlling bus overvoltage alarm |

Can be set (default value:242Vdc/121Vdc) |

|

|

16 |

Controlling bus undervoltage alarm |

Can be set (default value:198Vdc/99Vdc) |

|

|

17 |

DC output overvoltage protection |

Can be set (default value:290Vdc/145Vdc) |

Fault self- locking; must be rebooted |

|

18 |

DC output short-circuit protection |

Continuous short- circuit, normal protection |

Fault elimination; the module can be self- recovered |

|

19 |

DC feed insulation monitoring |

Max.384 |

Must be equipped with insulation monitoring module or insulation monitor |

|

20 |

Grounding resistance alarm of insulation |

Can be set, range: 1 KΩ-30KΩ |

Must be equipped with insulation monitoring module or insulation monitor |

|

21 |

Reliability Redundant backup |

N+1 |

When N≥10, suggest N+2 |

b. Functions

1. Achieve AC/DC conversion.

2. Provide an uninterrupted DC power supply.

3. Can be configured with independent battery routing-inspection equipment and insulation monitor.

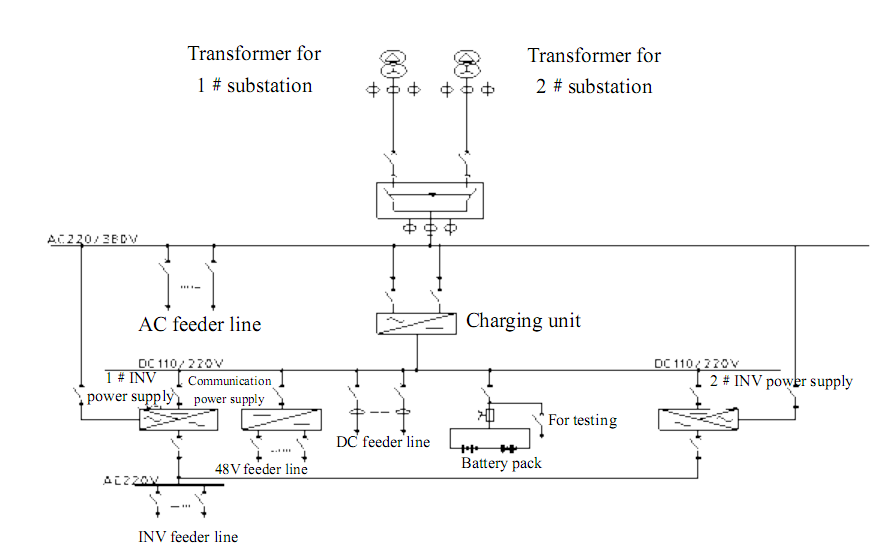

c. Schematic diagram

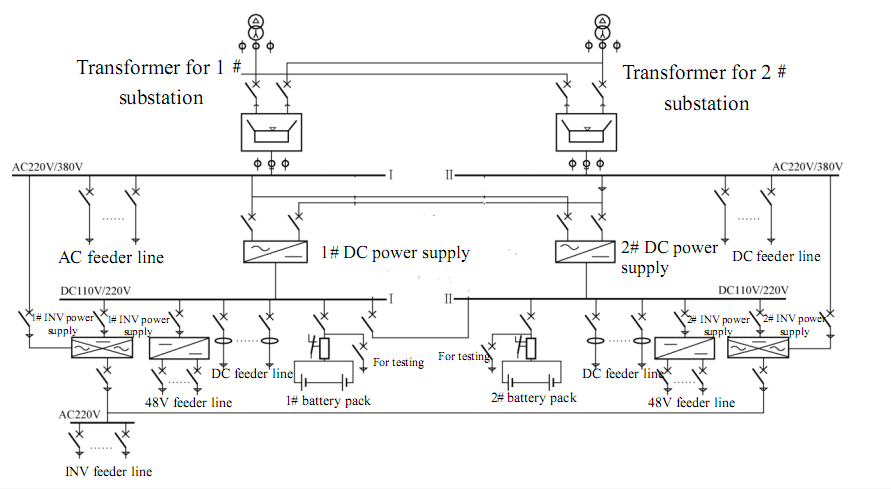

Principle of operation: When AC power is normal, for 2-circuit AC input, select one of them through AC switching device, and input to the system, then provide the power for charging device composed of N+x parallel charging modules through AC power distribution unit. The charging module converts the input three-phase AC power into DC power; on the one hand, charge the battery pack (at this time, generally adopt floating charging), and on the other hand, provide the power for closing bus, which will distribute the power to the relevant loads. Moreover, after reducing the voltage by using silicon-chain voltage-reduction device, the closing bus then provides the power for the controlling bus, which will then distribute the power to the relevant loads.

3. DC/DC communication power subsystem

a. Parameters

Table 3 Parameter List of Communication Power Supply

|

No. |

Items |

Indexes |

Remarks |

|

1 |

Rated DC output voltage |

48Vdc |

|

|

2 |

Ripple Vp-p |

≤200mV |

|

|

3 |

Precision of stabilized voltage· |

≤±0.5% |

|

|

4 |

Precision of stabilized current |

≤±0.5% |

|

|

5 |

Efficiency |

≥90% |

|

|

6 |

Input voltage |

Nominal value:DC220V/DC110V; Allowable variation range:±20% |

|

|

7 |

Unbalancedness of current-sharing |

Within the range of (50%~100%) Ie : ≤±5% |

|

b. Functions

Provide -48V DC power supply for the communication loads.

c. Schematic diagram

Principle of operation: Through high-frequency switch DC conversion technology, convert 220V\110V DC voltage input from the DC power supply to 48V DC voltage output.

4. Inverter (INV) /Uninterrupted power supply (UPS) subsystem

a. Parameters

Table 4 List of INV / UPS Parameters

|

No. |

Items |

Indexes |

Remarks |

|

1 |

AC output voltage |

Nominal value: 220Vac; Allowable variation range: ±1% |

|

|

2 |

Output voltage frequency |

Nominal value: 50Hz; Allowable variation range: ±0.5% |

|

|

3 |

AC input voltage |

220Vac±25% |

|

|

4 |

AC input frequency |

50Hz±5% |

|

|

5 |

DC input voltage |

220/110Vdc±20% |

|

|

6 |

Efficiency |

≥80% |

|

b. Functions

Invert DC to AC, and provide uninterrupted AC power supply.

c. Schematic diagram

Principle Block Diagram of UPS Special for Electric Power

Principle of operation: When AC input is normal, input the AC power to the rectifier circuit via the isolation of T1, and rectify and filter into a smooth DC power; then transmit the DC power to the inverter circuit, and convert it to single-phase AC power with constant frequency and voltage under the control of the controller, which will be sent via the isolation of T2 to static switch for output. When AC input is failure, change it to DC input, which will be sent via the anti-back diode to the inverter circuit for output. When the inverter circuit protection is shut down, switch it to bypass input through the static switch controlled by the controller, which will continue to provide the power for the loads.

5. Battery management parameters

Table 5 List of Battery Management Parameters

|

No. |

Items |

Indexes |

Remarks |

|

1 |

Charging voltage range |

198Vdc-286Vdc /99Vdc-143Vdc |

|

|

2 |

Battery pack floating charging voltage |

Can be set (default value: 243Vdc/121Vdc) |

Default by 108/54 pcs of single 2V battery |

|

3 |

Battery pack equalizing charging voltage |

Can be set (default value: 255Vdc/127Vdc) |

Default by 108/54 pcs of single 2V battery |

|

4 |

Equalizing charging time limit |

Can be set (default value: 10 h) |

When the battery equalizing charging time is over, transfer to the equalizing charging delay |

|

5 |

Regular equalizing charging |

Can be set (default value: 2,160 h) |

During the long-term running, carry out the battery pack equalizing charging regularly |

|

6 |

Battery pack temperature compensation |

-3mV/℃/2V, can be set |

Compensation center temperature: 25℃ |

|

7 |

Battery overcharging alarm |

Can be set according to battery pack capacity |

|

|

8 |

Battery overvoltage alarm |

Can be set according to battery pack voltage |

|

|

9 |

Battery undervoltage alarm |

Can be set according to battery pack voltage |

|

|

10 |

Number of battery voltage routing inspection |

Max.124 pcs/group |

Must be equipped with 4 pcs of battery voltage sampling box |

6. Other parameters

Table 6 List of Other Parameters

|

No. |

Items |

Indexes |

Remarks |

|

1 |

Insulation resistance |

≥10MΩ |

|

|

2 |

Insulation strength |

2,500Vac,5S,leakage current≤30mA, no arcing, no flashover |

|

|

3 |

Cabinet |

2260mm×800mm×600mm(H×W×D) |

Can be customized |

7. Integrated monitoring

a. Schematic diagram

b. Functions

1. Centralized & distributed monitoring system: make the monitoring module work more quickly and more stably, and the monitoring unit is designed according to the principle of three-level power monitoring system, which is responsible for collecting, processing, and uploading the data of power distribution and each module monitoring panel. Based on the operation state of DC system, the device can comprehensively analyze various data and information, so as to implement the control and management on the entire system. Functional modular design of monitoring system: when any sections fails, it can’t affect the normal operation of other sections; high reliability, easy for maintenance and replacement, and can communicate with each subsystem in a complete set of device, as well as can communicate with the host computer, where there are three optional background communication protocols (CDT, MODBUS, IEC61850) for user selection.

2. Large screen, color LCD touch display: friendly man-machine dialogue, and can display and modify various information and parameters in real-time, adopt multi-layer password protection, automatic error correction for operation and setting, powerful online help, intelligent battery management, large capacity historical alarm records and other functions; dynamic imagine display of schematic diagram: can intuitively and clearly display the operation state and alarm information of equipment and components, which will facilitate the maintenance personnel to maintain the equipment and find the fault points.

3. USB data download function: Through the USB data port, export DC data, battery data, insulation data, discharge data and other historical data, which will be easy for the data analysis on the system operation state.

4. History curve display function: can display battery voltage and current, positive and negative bus insulation voltage, resistance history curve and etc. within a month.

III. Economic Benefit Analysis (configuration comparison between AC/DC integrated power system and traditional AC/DC power system)

For the comparison between AC/DC integrated power system and traditional AC/DC power system, take the system configured with 2 circuits of AC incoming lines + 2 sets of charging modules + 2 groups of batteries (300A) as an example to explain the comparison items.

|

Comparison items |

Configuration of traditional substation power system |

AC/DC integrated power system |

Comparison |

Cost saved |

|

Function difference |

AC / DC separation design respectively configured with AC monitoring and DC monitoring, no unified communication interface; Equipped with operation battery pack and communication battery pack and UPS; Operation mode adjustment: AC and DC are individually executed; No intelligent secondary power distribution management; Respectively configured with lightning protection, and no comprehensive treatment can’t be carried out if there is any ripple wave interference.

|

The AC/DC integrated monitor is responsible for AC/DC monitoring via one communication interface; the communication battery pack is eliminated and substituted by directly hanging DC/DC power to the operation battery pack; UPS is eliminated and substituted by hanging INV power to the operation battery pack. Operation mode of substation power system is uniformly adjusted by the integrated monitor to ensure optimal operation of the system; Intelligent secondary distribution: intelligent lighting system, intelligent fan system, intelligent access control system, intelligent air conditioning system, and other auxiliary systems to realize intelligent operation; Substation power system configured with unified lightning protection and ripple wave treatment.

|

Integrated monitor = AC monitor + DC monitor; Integrated battery pack = operation battery pack + communication battery pack + UPS battery; Operation mode of substation power system is automatically adjusted; for the integrated design, the auxiliary systems are also intelligent; an integrated scheme solves problems in a unified and more effective mode.

|

Cost saved for monitors: about RMB 10,000; as well as some commissioning costs. Integrated battery pack, regardless of increased capacity, can at least reduce the number of charge modules and communication battery rooms. Cost saved: communication charging module, RMB 5,000 + communication battery room RMB 25,000 ≈ RMB 30,000;operation mode of substation power systems is automatically adjusted to reduce some operation costs. Intelligent operation of auxiliary equipment system can reduce some operating costs, and improve the operational reliability; can save the auxiliary equipment system intelligent transformation costs of RMB 20,000; Unified lightning protection and ripple wave treatment can reduce the repeated configuration and save some costs.

|

|

Subtotal: Functional investment can be saved about RMB 60,000, regardless of some uncalculatable costs. |

||||

|

Panel assembly |

AC panel: 2 set; DC panel: charging panel ,2 sets; feeder line panel, 2 sets; battery panel, 6 sets; totally 10 sets. Communication battery room: 1, where placing 2 sets of 48V/single 2V1000AH battery packs; 1 UPS, 12 panel cabinets required for computer and printer. |

AC panel: 2 sets + integrated monitor + emergency lighting; DC panel: charging panel + feeder line, 2 sets; feeder line + insulation detection panel, 1 set; communication DC/DC+INV power panel,1 set; battery + battery routing-inspection panel, 6 sets; totally 10 sets. Totally 12 sets, all feeder lines realize four-remotes, and also realize intelligent management of auxiliary units due to load difference. |

Simple and easy integrated connection reduces the workload of construction workers. |

Cable cost saved: RMB 2,000. |

|

Supplier |

4 |

1 |

Easy to contact and maintain |

Saved procurement working day : 10 days * RMB100/day = RMB1,000. |

|

Installation

|

Installation cost: 4 x RMB 2,000 = RMB8,000 (total maintenance cost for one person one time is RMB2,000) |

Installation cost: RMB2000 |

Easy to maintain, and can significantly reduce the long-term maintenance costs. |

Initial installation cost saved: about RMB6,000. |

|

Operation and maintenance |

4 profession |

1 profession |

Significantly reduce the number of operation and maintenance personnel and save some costs. |

Personnel expenses saved: RMB7,500/month (calculated according to RMB 2,500 / person salary), and can save about RMB 900,000 for 10 years. |

Conclusions :

For the system configured with 2 circuits of AC incoming lines + 2 sets of charging modules + 2 groups of batteries (300A), based on the above-mentioned comparison results, it can be found that the initial investment of the integrated power system has RMB 69,000 lower than that for a traditional power system and saves about RMB 900,000 regarding costs for long-term maintenance staff for 10 years. The above data is a conservative estimate and for information only, due to the intelligence, safety and other hidden savings and social benefits brought by the AC/DC integration can't be estimated.

IV. Wiring Diagram of Main Power Circuit for Integrated System

1. Wiring Diagram of Main Power Circuit for Single System:

2. Wiring Diagram of Main Power Circuit for Dual System:

Follow us